MPPIglobal Digital Solutions

Downtime & Defect Elimination

Mining Software |

Leading Software Solution for Global Mining & Metal Industry Process Plant Optimization

Improve Availability

Increase the availability of your critical assets within your Process or Fixed plant.

Reduce Costs

Equipment breakdowns are one of the most costly events that can occur.

Improve Utilization

Ensure you & your Team are effectively utilizing your equipment at all times.

Drive Improvement

Create a improvement framework that removes defect out of your business.

How it Works

A Solution Tailored to Optimize Mining Process Plants

Talk to our Team now to learn more about how our Solution can benefit your Operation.

Optimize Your Process Plants with Our Integrated Digital Solution

We offer an advanced, digitally integrated solution designed to seamlessly connect to your data historian or SCADA system. Our solution automatically generates loss events for configured assets when they stop or operate below target. These events are time-stamped, classified, and verified against your asset structure and time usage model. Based on your business rules, these loss events can automatically trigger a Root Cause Analysis Investigation as part of our Defect Elimination framework.

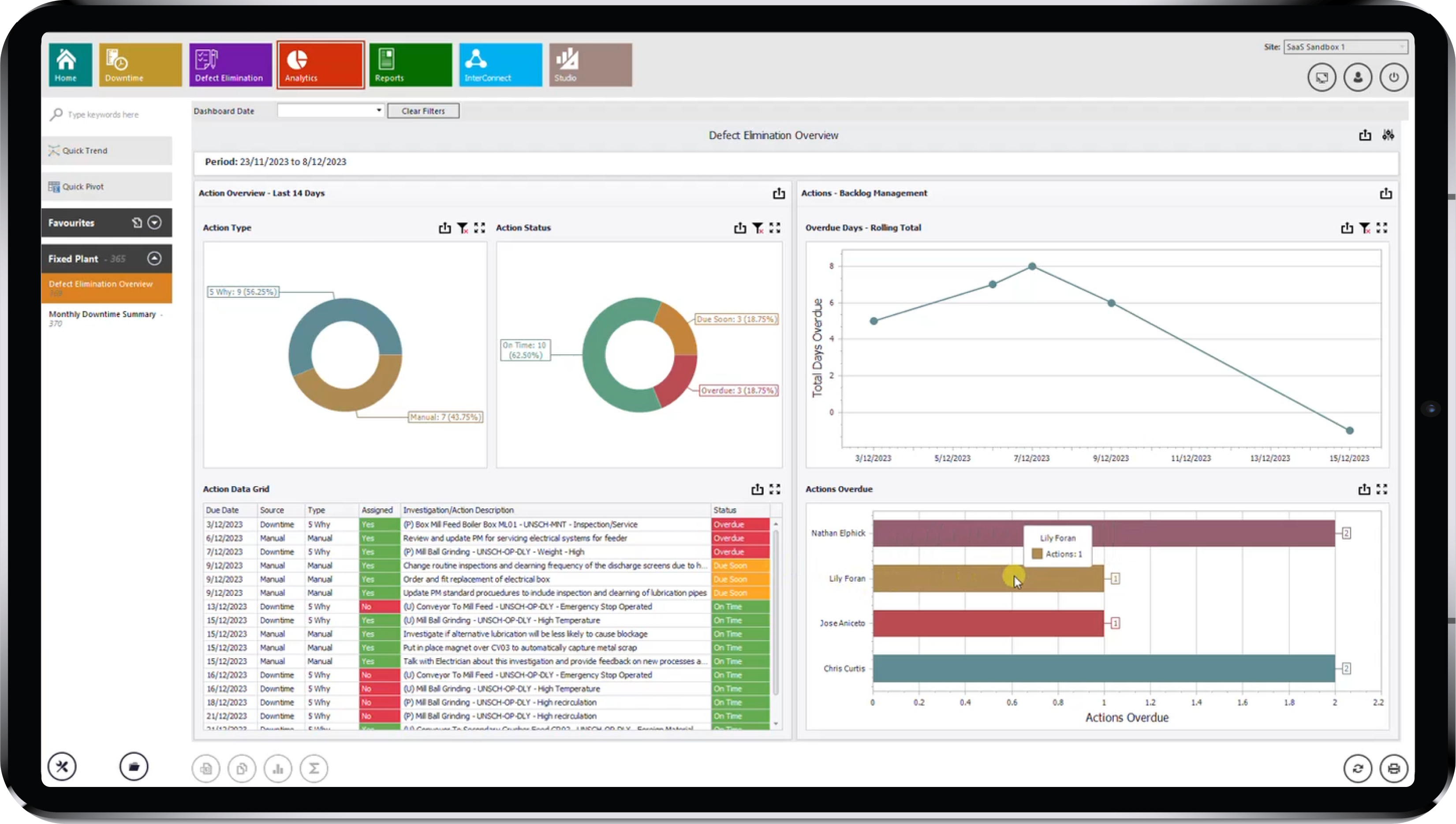

Our framework enables thorough investigation of loss events, the establishment of corrective actions, and their assignment for continuous improvement. Additionally, our solution features advanced analytics capabilities and a studio tool that allows users to configure and build custom reports and dashboards. This is particularly beneficial for operations lacking an independent reporting layer, as it enables the presentation of production data alongside downtime and defect elimination data, provided the production system is connected.Key Challenges addressed

Make a Change. Optimize your Business.

The business case for the Downtime & Defect Elimination Solution

Our analysis of manual downtime tracking using spreadsheets has revealed that at least 50% of loss data is either missed or recorded incorrectly. This primarily happens because events are often overlooked, and the manual process of analyzing asset signals to determine when an asset stopped, restarted, and reached target is prone to errors. As a result, Availability and Utilization numbers may be reported incorrectly, leading improvement programs to focus on the wrong areas.

Our Downtime and Defect Elimination Solution resolves this issue by automatically capturing all events, eliminating the need for manual intervention.

Manually tracking downtime events is time-consuming, repetitive, and prone to errors. It is estimated that at least 60 worker-hours per week are spent on manually checking, correcting, and verifying events across various resources and disciplines. This task, often handled by skilled professionals, equates to approximately 1.5 full-time resources. Given the high cost of mining resources and the current labor shortage, this wasted time can significantly impact operations.

Our Downtime and Defect Elimination Solution addresses this issue by automating the process, reducing wasted time, and allowing valuable resources to be redirected to more critical tasks.

When leveraged by the right people, downtime data can be incredibly powerful. However, many downtime systems fail to effectively disseminate critical information. Manual systems often depend on individuals sharing basic Excel spreadsheets, which is haphazard at best.

Our Downtime and Defect Elimination Solution addresses this issue with an integrated analytics layer. This feature automatically compiles reports, emails them to predefined lists, and provides real-time dashboards accessible to all relevant departments.

When failures occur, traditional downtime solutions only provide simple event data and lack the framework to investigate and correct the issue. This often results in recurring failures. Our Downtime and Defect Elimination Solution resolves this problem by automatically initiating Root Cause Analysis investigations based on the business rules you set.

These investigations are managed within our Defect Elimination framework, where corrective actions are established and monitored to prevent future occurrences of the same failure.

Solution Key Features

The benefits of the Downtime & Defect Elimination Solution.

Automatic Connections

Our solution automatically connects to site systems, eliminating the need for manual data transfer.

Downtime

Our solution features a unique user-friendly interface for classifications. It can be configured to display key metrics such as Mean Time to Failure (MTTF), Mean Time to Repair (MTTR), Availability, and Utilization.

Defect Elimination

Our system automatically generates investigations based on your business rules, serving as your complete improvement framework. It efficiently stores information and manages corrective actions to ensure continuous improvement.

Dashboards

Our solution allows dashboards to be configured as shared department dashboards visible to all, or as individual favorites accessible only to the logged-in user.

Studio Tool

Our solution features an inbuilt Studio Tool that empowers users to create their own reports and dashboards.

Reports

Our solution automatically compiles important information into reports, which can be configured for daily email delivery to your inbox.

Solution in Action

Solution

Walkthrough!

|

Click play now to watch the full Solution Walkthrough Video.

Book a Discovery Meeting Today

Our experts are ready to discuss your requirements in detail. Connect with us, and we'll provide a comprehensive guide and detailed pricing tailored to your needs.

About Us

Global Presence

We work within Global Mining & Metals Industry & have designed a Digital Solution that will improve any mine site’s revenue, productivity, efficiency & operational performance.